When choosing a tactical knife, it's important to consider the most common use cases it will face. Nearly any blade can serve in a self-defense situation, so focus on the activities you intend to perform regularly. With so many options to choose from, starting here will lead to the best design and materials from which to choose the perfect knife.

Everyday Carry (EDC) Knives

Everyday carry knives are lightweight, ergonomic and easy to take anywhere. They are typically foldable to save space and come equipped with pocket clips to make carrying simple.

Survival Knives

If you spend a lot of time outdoors or want to be prepared for any situation, survival knives are a great choice. Normally made with a fixed blade for maximum strength, survival knives often come with serrations designed to chop through wood and other fibrous material.

Duty Knives

A serrated knife is a good option for police officers and military personnel as they tend to stay sharper for longer. A good duty knife will hold an edge, resist corrosion and deploy quickly.

Hunting Knives

A hunting knife largely depends on the game being hunted. Small animals may require a smaller, sharper blade while larger game will require a tough edge.

Utility Knives

A general use utility knife can do a little bit of everything. It needs to be able to cut well and withstand frequent, extended use. Look for a knife with a corrosion-resistant blade that holds an edge well.

Blade Edge Types

After determining what kind of regular use your knife will see, the next step is deciding on an edge type. There are two types of knife edge: plain and combination. Each type has certain advantages better suited for specific cutting needs.

-

Combo Edge Knives

Combo edge knives feature serrations (saw-like points) on one half of the blade and a plain edge on the other half of the blade. A combo edge offers the hacking and chopping ability of a serrated edge and the sharp, precision cutting of a plain edge in one blade. This edge type is great for survival and hunting as its serrations cut easily through brush and wild game. Shop Combo Edge Tactical Knives

-

Plain Edge Knives

A plain edge blade does not have serrations. Its straight, sharp edge is designed to cut accurately and efficiently through softer surfaces. This kind of edge is often used as a duty knife as it sharpens quickly and resists corrosion. The ability to cut precisely makes plain edge blades great utility knives as well. Shop Plain Edge Tactical Knives

Fixed Vs. Folding

Another important aspect to consider when choosing a tactical knife is deciding between a fixed blade or a folding blade. Like plain and combo edges, fixed and folding blades each offer distinct advantages for different scenarios.

-

Fixed Blade Knives

Fixed blades are strong. Typically larger than folding blade, they are built tough, they're easy to clean and they deploy quickly. Their size and strength prevent them from breaking unexpectedly. Fixed blade knives are especially good for duty, survival and hunting due to their dependability. Shop Fixed Blade Tactical Knives

-

Folding Blade Knives

A folding blade retracts into the handle of the knife. As a result, folding blades are compact and easier to carry. Because of this portability, folding blade knives are popular for EDC, utility, police officers and military members. Shop Folding Blade Tactical Knives

Blade Styles

Uses, edge types and fixed/folding blades are very general considerations to make when choosing your knife. Blade styles, on the other hand, are specifically constructed for select cutting tasks. The style of blade you choose should (like every other aspect of a knife) be based on what you plan on using your knife for.

-

Drop Point Knives

As its name implies, the spine of a drop point knife blade literally drops in to meet the edge at a point. A drop point blade is designed for great balance and comfortable use. Their construction makes it easy to extend your finger along the spine of the blade to apply more pressure for accurate cutting and slicing. Shop Drop Point Tactical Knives

-

Clip Point Knives

A clip point blade looks like a standard blade with the top portion clipped off (this clipped portion can be straight or curved). Clipping the blade offers better puncturing capabilities due to the reduced surface area at the point and more control when cutting. The clipped side of the blade can even be sharpened into a second edge for maximum efficiency. Shop Clip Point Knives

-

Straight Back Knives

On a straight back knife blade, the spine of the blade does not curve. This rigidity offers more surface area on the edge. As a result, this kind of blade has good slicing capabilities, decent puncturing capabilities and great balance in its overall construction. Shop Straight Back Tactical Knives

-

Spear Point Knives

On a spear point knife blade, the spine and the edge both come to a point at a similar angle to resemble a spear. This kind of blade is unmatched in its piercing ability. The spear point makes for an intimidating and effective self-defense tool in case of emergency. Shop Spear Point Tactical Knives

-

Tanto Knives

The edge of a tanto blade angles off to meet the spine at a point. The result is one large edge and a kind of mini edge where the blade angles away. Tanto blades are a preferred style among military and law enforcement. The angular tip is tough and pierces well. Shop Tanto Tactical Knives

-

Wharncliffe Knives

A wharncliffe blade consists of a totally flat cutting edge and a spine that drops gradually to meet the blade tip; they're essentially reversed straight back blades.This blade type is best for precision cutting. The flat edge allows for long, smooth cuts across level surfaces. Shop Wharncliffe Tactical Knives

-

Trailing Point Knives

On a trailing point knife blade, the cutting edge curves upward to meet the spine at a point above the handle. The design provides more edge surface area good for slicing and skinning. Trailing point blades offer great puncturing capabilities as well. Shop Trailing Point Tactical Knives

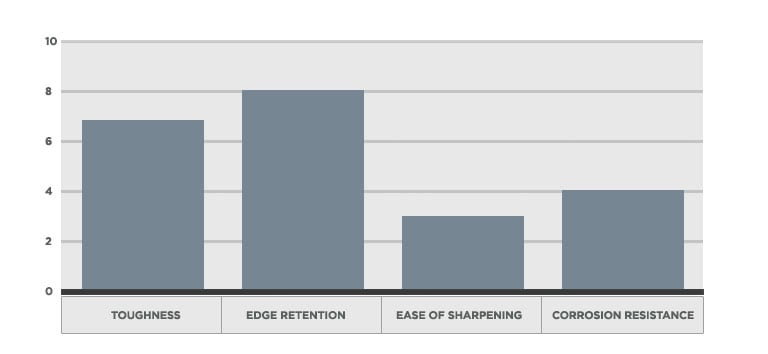

Blade Material

While blade style is a good indicator of what a knife is built for, a more telling characteristic is the blade material itself. Like other knife qualities, you should choose the material of a blade based on what the blade will be used for. These are some common attributes of a knife blade that are most directly affected by material.

Blade strength: A blade's ability to resist breaking or fracturing

Edge retention: A blade's ability to stay sharp without the need for frequent sharpening

Corrosion resistance: A blade's ability to avoid deteriorating due to humidity, moisture, salt or other chemical processes.

Ease of sharpening: A blade's ability to be sharpened without much difficulty

It is very rare for a knife to exhibit proficiency in all of these categories. Most of the time, a blade will only excel in one or two as there is no blade material realistically capable of performing well in all of them.

Most blades are made of steel because of its rigidity, malleability and ability to resist corrosion. Steel is an iron and carbon alloy with high tensile strength and relatively low cost. Blade manufacturers will often add elements to steel such as vanadium for extra strength or additional carbon for corrosion resistance. Here are some common types of steel found in knife blades and their practical applications.

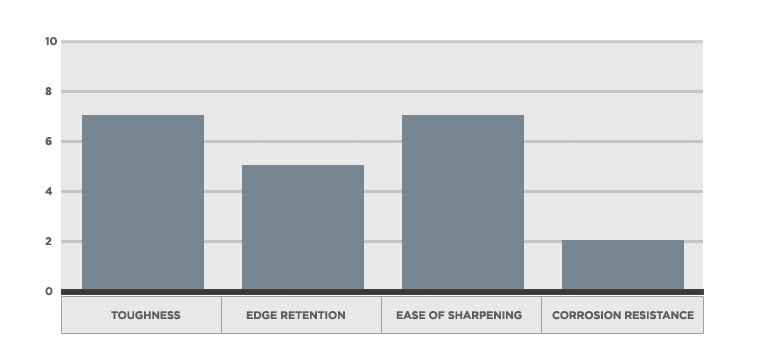

High Carbon Steel Knives

All steel is made up of iron and carbon, but some steel is made with higher levels of carbon than others. This high carbon steel is harder and stronger than typical steel. The added carbon tends to make the steel more brittle though and, as a result, a high carbon steel blade may be prone to chipping or shattering. The most common high carbon steel, 1095, makes for an excellent blade material. Shop High Carbon Steel Tactical Knives

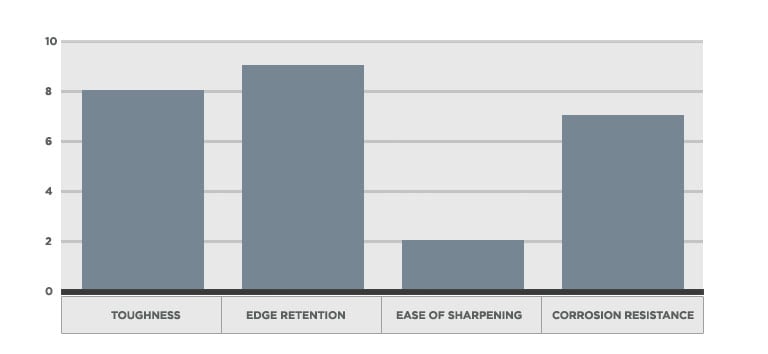

High Vanadium Steel Knives

High vanadium steel is tough against both the elements and impacts. Its rigid construction resists corrosion and rust very well. It also holds an edge and requires minimal sharpening, but when it does become dull, sharpening can be difficult. Shop Vanadium Steel Tactical Knives

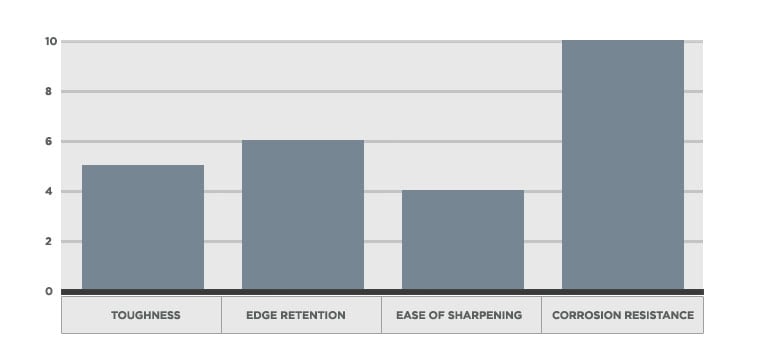

Stainless Steel Knives

Stainless steel is one of the most commonly used metals in commercial products. Its 11% chromium construction means it resists corrosion very well and its minimum 1.2% carbon content makes it exceptionally durable. There are dozens of alloys that fall under the stainless steel umbrella, but some find their way into knife blades more than others. Shop Stainless Steel Tactical Knives

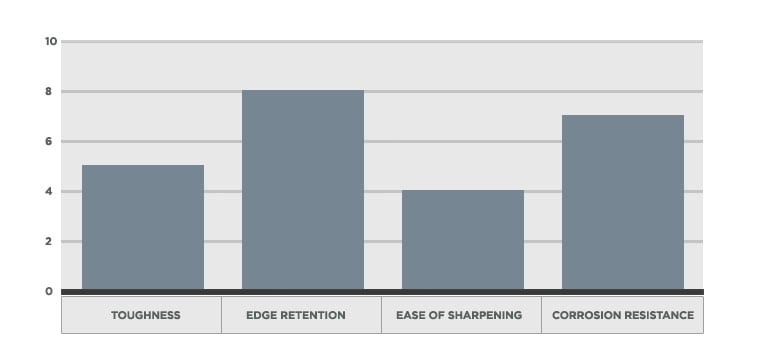

CPM-S30V Knives

Featuring a metal mix that results in a very refined grain, CPM-S30V is a sharp, tough stainless steel. It resists corrosion just as well as any other type of stainless steel and is relatively easy to sharpen, making it a great choice for a knife blade. Shop CPM-S30V Tactical Knives

420HC Knives

The "HC" in "420 HC" stands for "high carbon." It is generally considered the best in the 400 series of stainless steel alloys. Like other high carbon blades, it is tough and resistant to abrasion, albeit a bit brittle. Shop 420HC Tactical Knives

8CR13 Knives

8CR13 steel offers a similar level of performance to high-end steels like CPM-154 and LC200N at a more economical price. Though it is neither as corrosion-resistant nor as hard as premium steels, its level of performance is still great considering its relative cheapness. Shop 8CR13 Tactical Knives

Thermoplastic Knives

It may seem strange, but not all knives are made of metal. Special plastic mixes offer a great balance of sharpness without the need to worry about rust and corrosion. A sharp thermoplastic knife makes for a dependable, lightweight self-defense tool. Shop Thermoplastic Tactical Knives

Tool Steel Knives

Tool steels are, as their name implies, normally found in screwdrivers, wrenches, hammers, etc. Like tools, knife blades made from tool steel are very hard and very durable. D2 is the most common tool steel used in knife making. It holds an edge well over a very long period of time but can be quite difficult to sharpen. Tool steel knife blades are long-lasting and very dependable. Shop Tool Steel Tactical Knives

Handle Material

Blade material is one of the most important aspects to consider when choosing a knife. Handle material is important as well, as your grip on a knife directly affects how the knife performs. The perfect knife will feel comfortable in your hand and will be easy to use based on its shape and material. Here are some common handle materials and their defining characteristics.

Composite

Composite knife handles feel comfortable in the hand and are durable enough to last quite a while. Due to the abundance of chemicals and materials that can potentially make them up, composite handles are very versatile. Zytel, Ultramid and Kraton G are popular composite materials often found in knife handles.

Aluminum

Aluminum gives a knife a solid, well-built feel without the added weight of a heavier metal. This makes for a light knife that is easy to carry all day.

G10

Growing in popularity within recent years, G10 is a hard, lightweight and strong fiberglass laminate material. It keeps its form and, because of a lack of metal in its makeup, it is not prone to corrosion-resistance.

Leather

While leather is most often used in footwear, some knife handles feature it for the same reason boots and shoes do: it is hard, tough, and wears very well over time. Leather handles are frequently found on military-style fixed blade knives.

Nylon

Nylon is one of the most common knife handle materials. Tough, resistant to many chemicals and stable at extreme temperatures, nylon is an excellent, cost-effective handle material.

Rubber

Rubber is well-known for its grippy texture. It is used in knife handles for this very reason — rubber knife handles are very durable and easy to grip for precise cutting.

Steel

Blades aren't always the only part of a knife made of steel; knife handles sometimes feature a steel construction as well. While a steel handle doesn't offer the same comfort in the hand as leather or rubber, the great blade properties of steel apply in a handle, too — toughness, corrosion-resistance and the ability to withstand long-term wear and tear.

Deployment Methods

If you've selected a folding knife, deployment method is an additional aspect that needs consideration. In an emergency situation, opening a knife quickly can help to shave precious seconds off your response time. The following deployment methods are found on virtually any knife on the market; make sure to pick the one that's right for you. To see these deployment methods in action, take a look at our video on how to open and close a tactical knife.

-

Thumb Stud

A thumb stud is a lug on a knife blade found near the hilt. While thumb studs can take some getting used to and may hurt a bit when pushing a knife open, they are undoubtedly a quick, effective method of deploying a blade.

-

Thumb Hole

Opening a knife with a thumb hole is a little simpler than using a thumb stud. A hole in the blade allows the use of your entire thumb pad (or even a thumb and index finger) to deploy the blade. Using the whole thumb pad helps to distribute pressure for a more smooth deployment.

-

Flipper

This extended piece of metal protrudes out of the back of the handle when the blade is closed. To open the knife, simply push down on the flipper with your forefinger. A flipper is one of the best and easiest deployment methods for a folding knife.

-

Nail Nick

Often found on smaller pocket knives, the classic nail nick requires the use of a fingernail to open the blade. If your fingernails are short, it may be best to avoid a knife that deploys via nail nick.

Locking Mechanisms

Once you've got your knife open, it's important that it doesn't snap closed while you're using it. Tactical knives are made with a variety of locking mechanisms. These locks are a safety feature to ensure the blade doesn't come down on your fingers. The blade of a locked folding knife will stay deployed only until you decide to engage the locking mechanism and close it. Here are some of the most common types of locking mechanisms on tactical knives. To see how they work, be sure to watch our video on how to open and close a tactical knife.

Liner lock

One of the most common and easy-to-use knife lock mechanisms, the liner lock is a piece of metal inside the handle of a knife. When the knife blade is closed, it holds the liner lock in place. The lock's tension naturally pushes it away from the handle and under the blade, though, so when the blade springs open, the liner slides into place and blocks the blade from closing. To disengage the lock, simply push it away from the blade and toward the handle, and slide the blade closed. Liner locks are advantageous for their solid construction. It's very hard to accidentally disengage a liner lock, ensuring the blade only closes when you want it to close.

Frame Lock

A frame lock is very similar to a liner lock — it slides into place under the blade when the knife springs open. Instead of a built-in piece of metal, though, a frame lock is just a portion of the frame itself designed to lock the blade into place. The process of engaging a frame lock is the same as engaging a liner lock: just push it out of the way and close the blade. Like a liner lock, it's nearly impossible to accidentally disengage a frame lock.

Lockback

A lockback is an exposed piece of metal on the spine of a tactical knife. A notch at the end of the lock (near the hilt) hooks onto a notch built into the blade, holding the knife firmly in place when it's open. Closing a lockback knife requires two hands; push down on the exposed part of the spine with one hand to disengage the blade, and swing the blade closed using the other hand. This two-handed requirement ensures that the knife blade will only close when you deliberately depress it, keeping your hands and fingers safe while you use the knife.

Button Lock

The button lock is probably the easiest way to close your knife. A spring in the handle is attached both to the knife blade and to the button. Pushing the button down unlocks the blade and allows the spring's tension to take over. Simply push the blade against the tension (while holding the button down) to close your knife. While knives with button locks are very easy to close, that's also their danger: they're easy to close. Make sure to avoid accidentally pressing the button during use so the blade doesn't close on your fingers.

As is probably clear by now, tactical knives are very diverse tools. Between blade types, blade lengths, blade materials, handle materials, locking mechanisms and a myriad of other features, finding the right knife can be an overwhelming process. The best thing to do, though, is consider what you're going to use your knife for and find the features to match. Once you narrow it down, it won't be nearly as difficult. Use the abundance of knives out there to your advantage. It may take some effort to sift through, but the long list of useful features means your perfect tactical knife is just a little research away.

Did you find this article helpful?